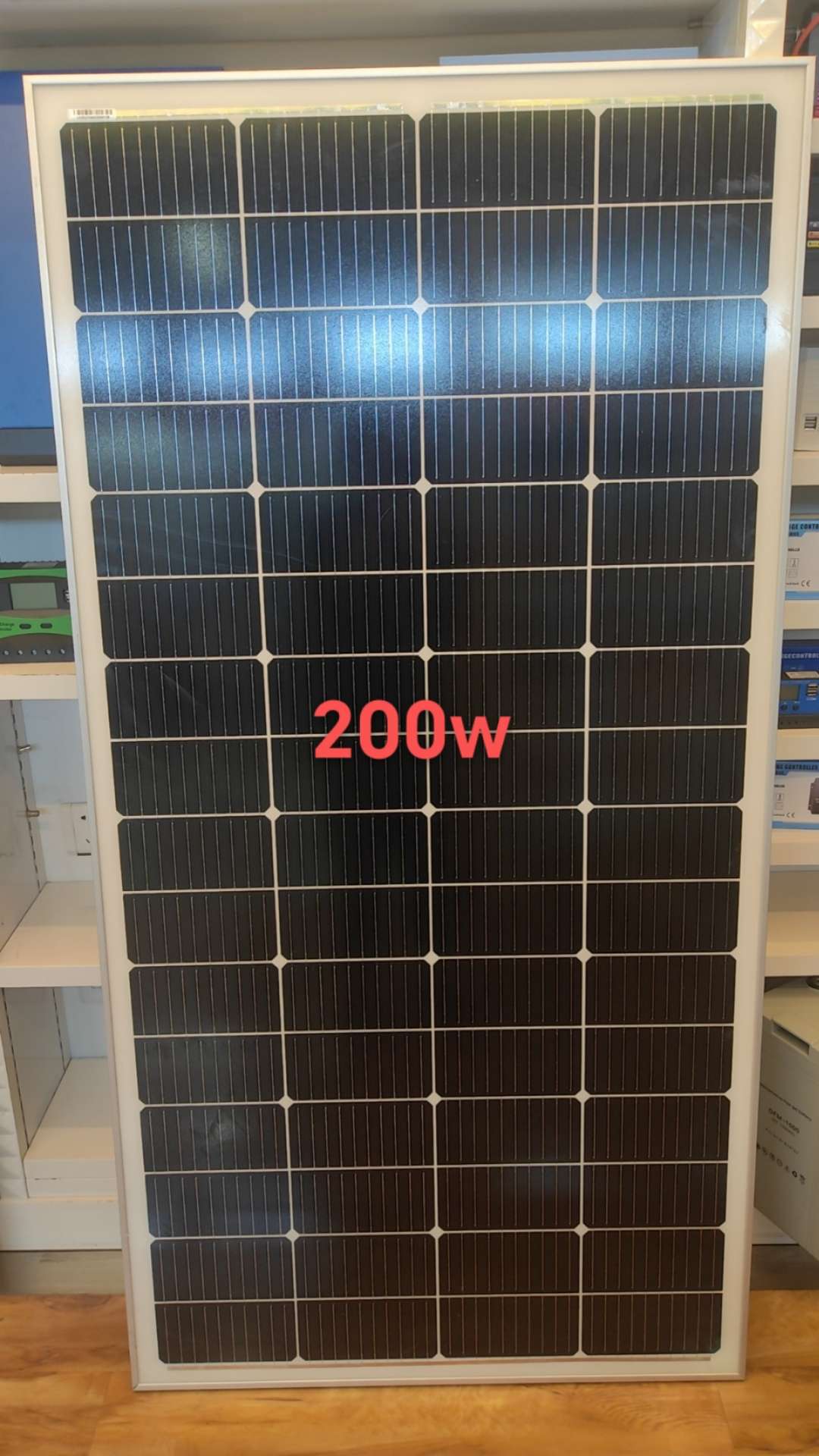

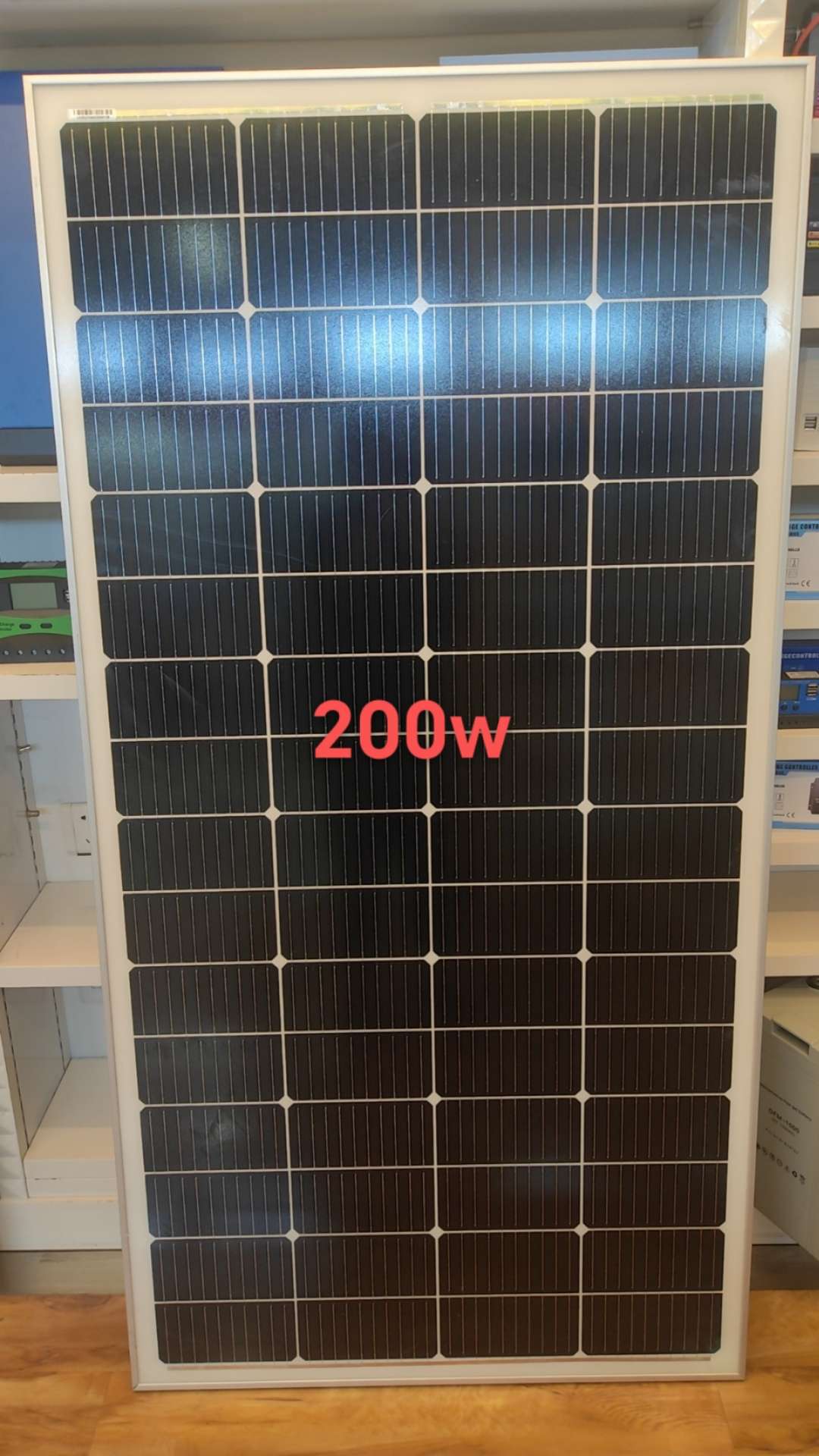

As the pace of the global energy transition accelerates, more and more households and businesses are looking for sustainable, stable sources of electricity. In this context, the new generation of 200-watt monocrystalline silicon solar panels stand out-not only by virtue of its efficient energy conversion ability to win the favor of the market, but also with its excellent environmental adaptability and intelligent design to become an important representative of the field of green energy.

Decoding the technological innovation of 200W monocrystalline silicon solar panels: how to redefine green energy efficiency

This product uses a high-purity monocrystalline silicon substrate, combined with advanced passivation emitter technology and multi-gate line layout, so that the photoelectric conversion rate to achieve the industry-leading level. Even in the case of weak light such as early morning or dusk, a large proportion of the rated power can still be stably produced.

More importantly, this series of panels have highly modular installation characteristics, whether you want to build a home off-grid system, or expand the scale of commercial grid-connected power station, can quickly find a matching space planning scheme. By connecting multiple units through standardized plug interfaces, the entire array can be deployed and debugged in a short time.

In-depth analysis: Why choose this solar panel as the power pillar of your home or business

Excellent weather resistance breaking the limits of extreme weather use

Low illumination compensation technology continues to supply energy on cloudy days

Intelligent temperature control management system solves heating loss pain points

Real Case Witness: Global Users Present the Changing Power of the PV System

"Self-built houses in remote mountainous areas have finally realized constant power supply, refrigerators, televisions, and air conditioners"

Rigorous standards behind manufacturing: extreme polishing at every step from laboratory development to mass production

- ISO international certification production process system

- The full-automatic optical positioning cutting machine accurately carves every millimeter of detail, and closes the purification workshop in the whole process to prevent the risk of impurity mixing. Each finished product must undergo at least three infrared scans to screen potential defect points.

- Accelerated aging simulation test report disclosure

- After being placed in a special climate chamber for a day and night cycle alternating test for more than one month, the surface gloss attenuation value is lower than the 1% threshold index and far better than the performance level of similar competitors.

- Patent border connection structure innovation highlights

- The self-developed snap-in coupler allows a certain angle offset buffer space between adjacent modules, which not only improves the overall assembly flexibility but also greatly reduces the stress concentration problem caused by traditional screw fixing.